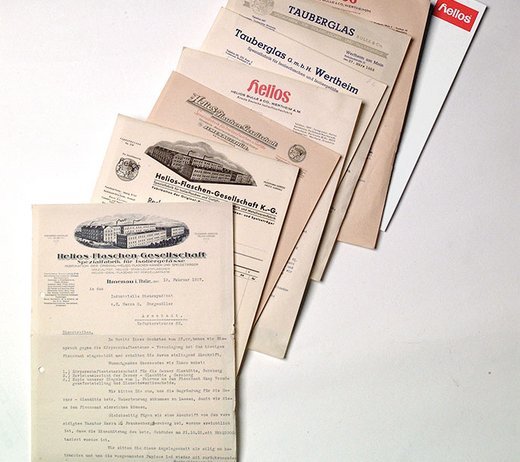

Helios is a family business based in the heart of Germany. With a tradition since 1909, we are the oldest manufacturer of insulated vessels in Europe. The company has grown steadily despite many crises and has asserted itself in a difficult market environment. We see ourselves as a brand manufacturer with the most extensive range in this sector.

We supply all regions of the world. At three locations in Wertheim and at our subsidiary in the Czech Republic, around 100 employees work every day to ensure that our customers always receive products of the highest quality - from consulting to production and shipping.

As the market leader in the professional sector, we are particularly committed to improve the quality and function of our products constantly. Our dishwasher-proof thermos jugs have been reliable partners to professionals for many years. They have become indispensable in hospitals, care homes, canteens, hotels and catering businesses.

Our vision: Everyone who uses a Helios product feels the quality and innovation that goes into our products - simply a bit more quality of life through the enjoyment of perfectly tempered beverages. And that is what we stand for:

- Quality

- Innovation

- Sustainability

- Trust

Be inspired by the design, functionality and spirit of our products. We attach great importance to use resources carefully. Helios vacuum vessels are durable and designed for long-term use.

Three companies Together we are strong!

Our company group consists of three companies that complement each other perfectly. Each of the companies is a specialist in its market. From the production of the individual plastic parts to the fully assembled vacuum jug. This is how we create value and reliability for our customers. On this basis, we are extremely optimistic about the future!